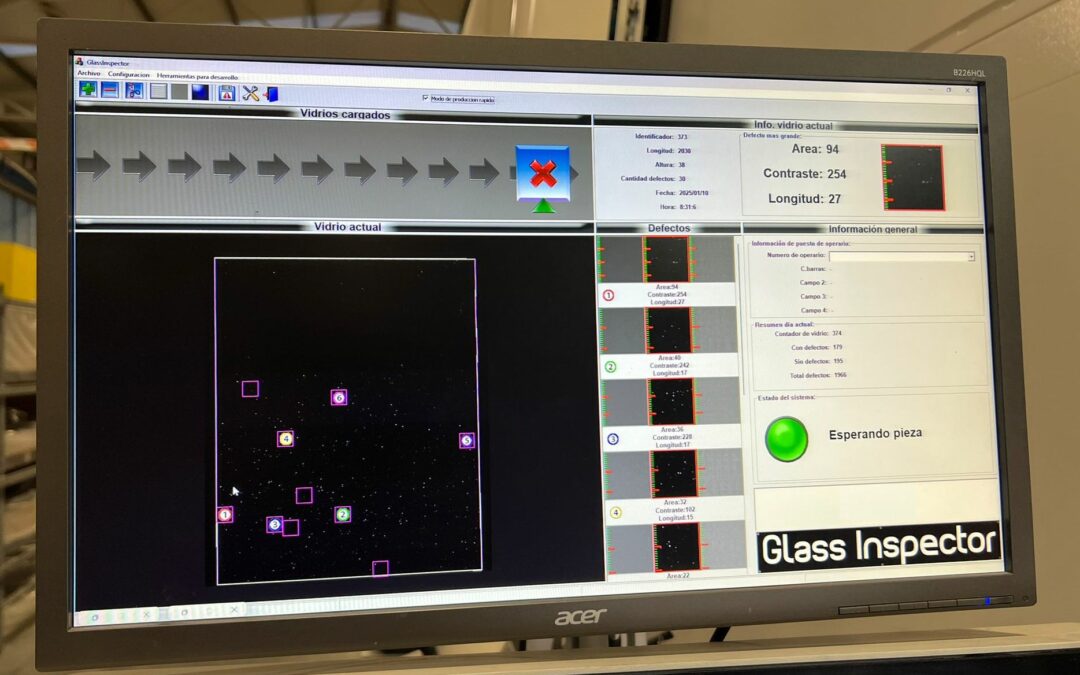

I’m going to check it and the washing machine is working perfectly… so what appears on the screen of my Glass Inspector…?

I’m looking at this laminated glass with my eyes and I don’t see this star shower that appear on my screen. I urgently call my glass supplier to whom I just sent this image , and he tells me that the PVB manufacturer has had a problem in its manufacturing, and that what I am seeing thanks to my Glass Inspector are thousands of microbubbles that, thanks to the system to see the real image of the glass “true image” I have been able to detect and prevent it from reaching my final customer …..

This is a true story from this beginning of the year 2025.

The “True Image” technology integrated into the Glass Inspector system is a ground-breaking feature that sets it apart from conventional glass inspection systems. This advanced imaging capability ensures unparalleled precision, efficiency, and reliability in detecting and analysing defects. Here’s why having the Glass Inspector equipped with “True Image” technology is crucial;

True Representation of the Glass Surface:

“True Image” technology captures high-resolution, distortion-free images of the glass surface, enabling the detection of even the smallest defects.

Instant Feedback:

The system processes and analyses data in real time, offering immediate insights into the quality of each glass sheet. This allows manufacturers to address issues promptly and minimize production downtime.

Dynamic Monitoring:

“True Image” ensures consistent monitoring of the glass quality throughout the production process, ensuring no defective piece goes unnoticed.

Glass Inspector born to inspect your glass