THE 3 MAIN CAUSES OF THE APPEARANCE OF WHITE HAZE – NIEBLA BLANCA -NEBBIA BIANCA – BRUME BLANCHE -NÉVOA BRANCA …….. CALL IT IN YOUR LANGUAGE WHATEVER YOU WANT.

The world market increasingly demands higher quality tempered glass and a zero defect policy.

GLASS INSPECTOR has developed a new GLASS INSPECTOR 4D solution to continuously monitor white haze on all processed glass. This allows glass processors to react quickly to correct potential processing issues in their tempering furnace, as well as ensure only optimum quality is shipped to their end customers.

The 3 most common reasons for the appearance of white mist in the tempering process are:

1st Control of the state of the ceramic rollers in the tempering furnace:

The residue on the furnace ceramic rollers, this residue then causes small scratches on the surface of the glass. Examine the surfaces of the rollers. Are they rough, cracked or brittle? Are there solid particles on the surfaces? If so, take appropriate corrective action.

2º Control of the cleanliness of the tempering furnace:

It is important to make sure that there is no possibility of dust getting into the furnace. General cleanliness of the production environment is key. The operators of the tempering furnaces do not take into account that the cleaning of the rollers on the loading table of the furnace is essential when the glass that is going to be tempered drags this dirt into the interior of the furnace. Also, be careful to inspect the insulation. The furnace doors must be in perfect working order to prevent particles from entering the machine and adhering to the ceramic rollers.

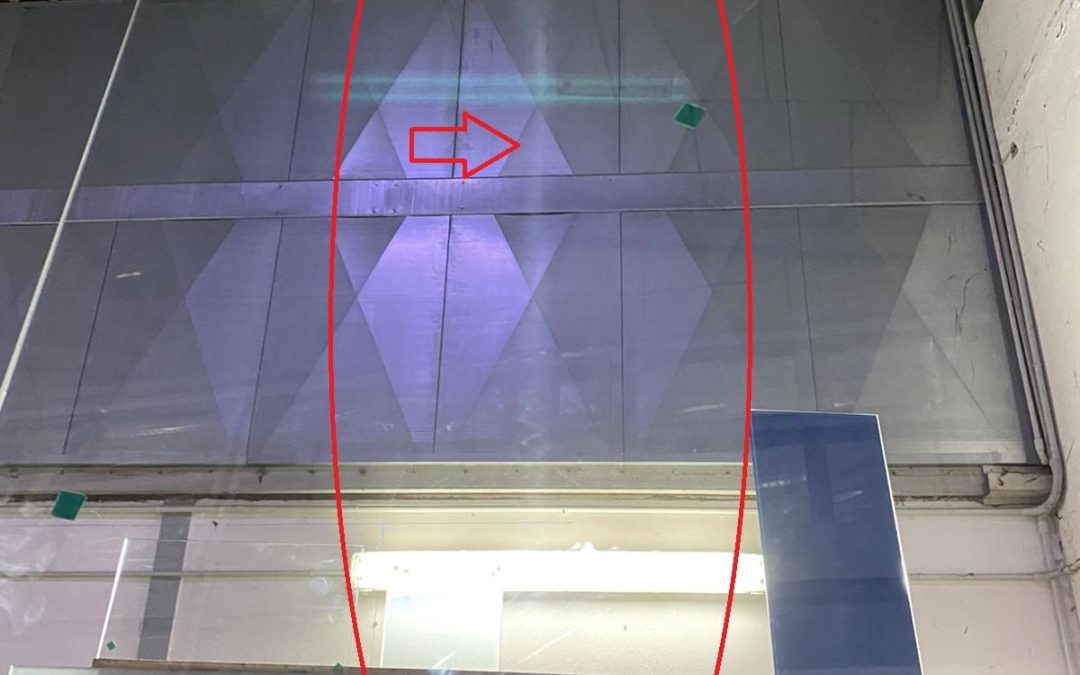

3º Leveling of the ceramic rollers of the tempering furnace

The leveling of the rollers is very important. If they are not adjusted correctly, the white haze can be caused by too strong mechanical pressure between the glass and the rollers that are at different working levels inside the furnace, causing micro-scratches that create the White haze effect.

GLASS INSPECTOR 4D White haze control + optical distortion + planimetry + anisotropy ….. All in one machine.