Services

Adaptable to all types of industrial environments

SOLUTIONS

GlassInspector® Cloud

Industry 4.0 comes with access to inspection database through our apps. Online demo available.

Defects signalling

Patented system to point defect directly on the glass by means of colour LEDs lights.

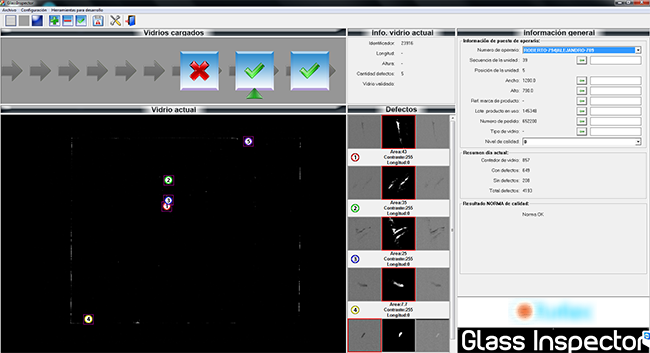

SOFTWARE

Parameterized and configurable software with the possibility of adding multiple profiles depending on levels of quality.

Integration with plant software

Our system has different methods for accessing and communication inspection information for automatic systems.

Technical support

We offer technical support and assesment for solving queries and incidents for both remote or in-person.

Why

GlassInspector®?

Reasons for which you will prefer GlassInspector®

Glass Inspector improves production process through defect detection.

• CUSTOMISABLE DESIGN TO CLIENT REQUIREMENTS

• PARAMETERIZED AND CONFIGURABLE SOFTWARE

• INTUITIVE USER-FRIENDLY INTERFACE

• ACCESS TO PRODUCTION INSPECTION INFORMATION

• INTEGRATION WITH TRACKING SYSTEMS

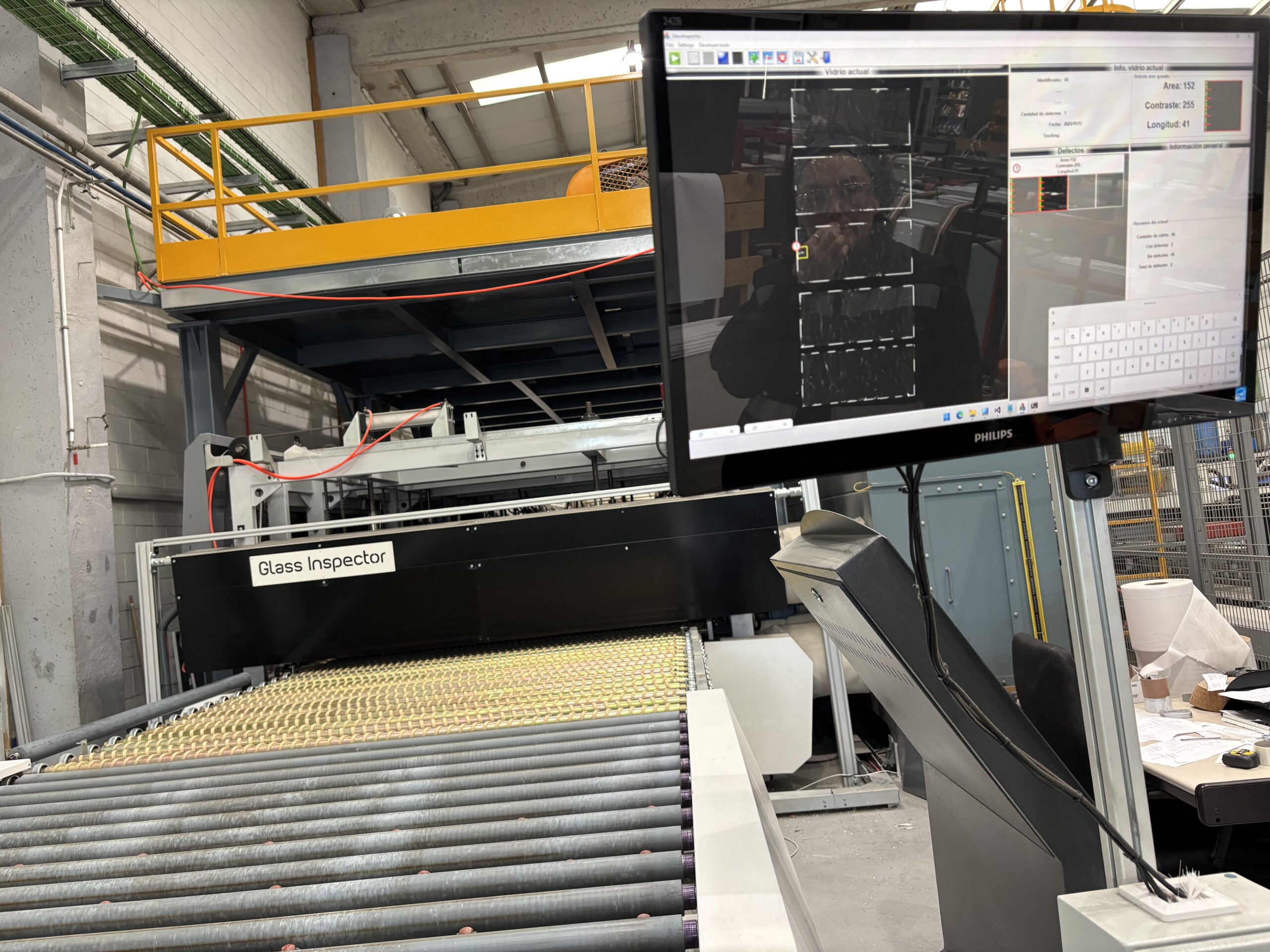

VERTICAL GlassInspector®

Vertical GlassInspector® has been designed and entirely manufactured by Spanish technicians.

Due to their ease of integration, Vertical GlassInspector® can be installed in any type of isolated glass production line either new of operational.

Can be also installed in any kind of vertical flat glass manufacturing such as edge and drill control numeric centres.

GlassInspector® requires very little space for adapting to any type of double glazed glass either new or installed.

For GlassInspector® installation and assembly it is not necessary to move production line from where it is located, nor does it modify your line in any way.

Equipment main technical characteristics:

- Modular scanner so maintenance is very simple.

- GlassInspector® saves data of every scanned piece, so that in case of a client complaint it is posible to trace the defective piece information such as manufacturing process and machine operator responsible of the production.

- You will only need 25 millimeters between line components. We insist in the fact that it is not necessary to move it.

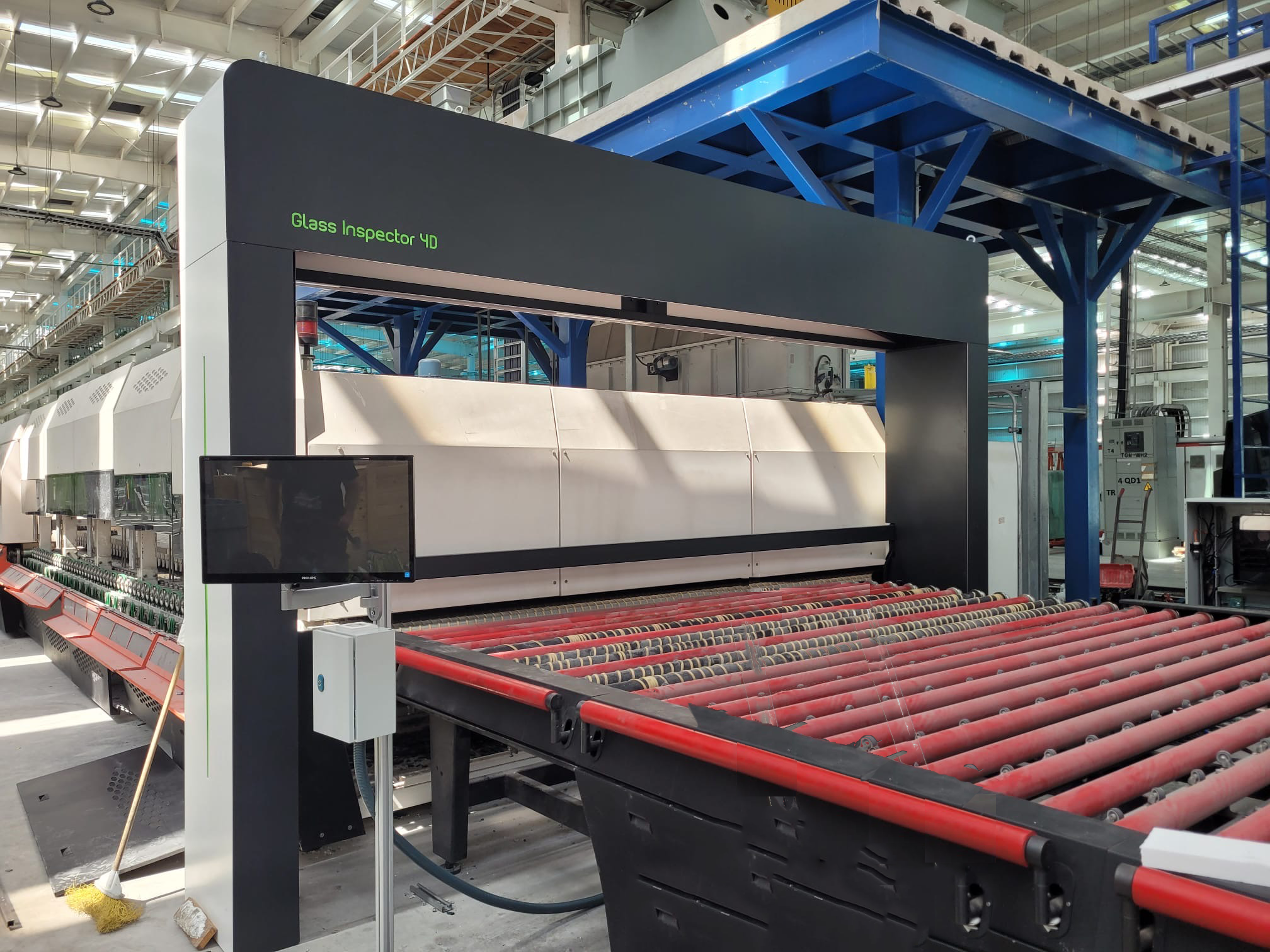

HORIZONTAL GlassInspector®

Horizontal GlassInspector® has also been enterely developed and manufactured by Spanish technicians.

Because of It’s ease-of- installation, Horizontal Glass Inspector can be installed in any type of running tempering furnace, in production lines of float glass, laminated glass and in all kind of horizontal manufacturing line.

The result is technical information of every manufactured piece of glass such as superficial quality and glass mass. Horizontal Glass Inspector takes up very little space to be adapted to any type of glass production line either tempered or laminated.

Equipment main technical characteristics:

- Modular scanner so maintenance is very simple.

- GlassInspector® saves data of every scanned piece, so that in case of a client complaint it is posible to trace the defective piece information such as manufacturing process and machine operator responsible of the production.

- You will only need 25 millimeters between line components. We insist in the fact that it is not necessary to move it.

GlassInspector® TEMPER

GlassInspector® TEMPER

The GlassInspector® TEMPER has also been developed and manufactured entirely in Spain by Spanish technicians.

Due to its ease of installation, it can be mounted in any existing Tempering Furnace.

The result is technical information on each piece of glass manufactured in your tempering furnace, especially on the surface quality and its glass mass. It needs very little space for its adaptation to any type of tempering line.

A scanner developed by the Glass Inspector technical team, capable of detecting the 4 main defects that tempered glass can have:

- White haze

- Optical distortion.

- Planimetry.

- Anisotropy.

Glass Inspector TEMPER , all these features in a single device… you can’t ask for more

GlassInspector® TEMPER QUALITY

GlassInspector® TEMPER QUALITY

The GlassInspector® TEMPER QUALITY has also been developed and manufactured entirely in Spain by Spanish technicians.

Due to its ease of installation, it can be mounted in any existing Tempering Furnace.

The result is technical information on each piece of glass manufactured in your tempering furnace, especially on the surface quality and its glass mass. It needs very little space for its adaptation to any type of tempering line.

A scanner developed by the Glass Inspector technical team, capable of detecting the main defects that the glass can have:

- Stripes.

- Transparent stains.

- Finger marks.

- Remnants of sticker.

- Bubbles.

- Some layer failures

Glass Inspector TEMPER QUALITY , all these features in a single device.

The following defects can be identify at normal speed production:

DEFECT CATEGORY | DEFECT DESCRIPTION | TYPE OF DEFECT |

Glass surface contamination | Defects in glass surface that can be removed with proper cleaning | Dirt, fingerprints, stains (produced by brushes and rollers), oil drops, water drops |

Glass surface damage | Physical damage of the glass surface caused by handling, cutting table, edging machine, etc. | Scratches, dots and chips. |

Defects inside the glass | Defects that are inside the glass and have not been caused by handling. | Bubbles and particles inside the glass. |

Low-E coating defects Solar control defects | Damage and defects in coat applied to the glass. They are defined and can | Pin holes, scratches, stains, coating distortions and coating voids |

Customizable software

Parametrized and configurable software with the possibility of adding multiple profiles for different levels of quality, fields, custom controls, etc.

We offer more than products

At GlassInspector® we offer more than products, we offer customized solutions for each client from the design of the inspection machine to the software. Thanks to the combination of our know- how with correct use of all resources we have.

GlassInspector® Cloud, web application available for inspection data consulting.

Access to inspection report through web application, glass identification using a code or scanning with camera (mobile phone or webcam) with different access profiles for managers, clients and suppliers.

Your information is secure

Save your inspection data through backups in local and or remote storage so that in case of a disaster you can recover all the information collected to date.

Frequently Asked Questions about the Glass Inspector

Have questions about how Glass Inspector works or how to install it? Here’s everything you need to know.

DOWNLOAD

CATALOG

Do you need a glass inspection system?

Contact usOur work in images

EXTENSIVE EXPERIENCE IN THE MARKET.

WE LEARN MORE AND IMPROVE WITH EACH INSTALLATION.

We are here

Calle Arretxe Kalea, 15

20730 – AZPEITIA – GUIPÚZCOA, ESPAÑA