servicios

Adaptables a todo tipo de entornos

SOLUCIONES

Nos adaptamos a las necesidades de nuestros clientes para ofrecerles las mejores soluciones a través del codesarrollo.

GlassInspector® Cloud

Llega la industria 4.0, acceso a los datos de inspección mediante aplicación web. Demo online disponible.

Señalización de defectos

Sistema patentado para la localización de defectos mediante leds de colores, directamente en el vidrio.

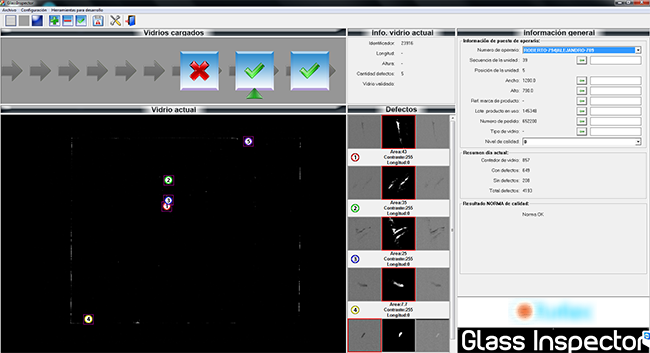

SOFTWARE

Parametrizado y configurable, con posibilidad de añadir multiples perfiles para distintos niveles de calidad.

INTEGRACIÓN CON SOFTWARE DE PLANTA

Disponemos de varios metodos para la consulta y comunicacion de los datos de inspeccion para sistemas automaticos.

SOPORTE

Soporte técnico y asesoramiento, resolvemos tus dudas e incidencias, tanto de forma remota como in-situ.

¿Por qué

GlassInspector®?

Es por esto por

lo que te quedarás con GlassInspector®

Mejoramos el proceso de producción mediante la detección de defectos en vidrio.

• DISEÑO QUE SE ADAPTA A TUS NECESIDADES

• SOFTWARE PARAMETRIZADO Y CONFIGURABLE

• INTERFAZ DE USUARIO FACIL E INTUITIVO

• CONSULTA DATOS DE PRODUCCIÓN

• INTEGRACION CON SISTEMAS DE TRACKING

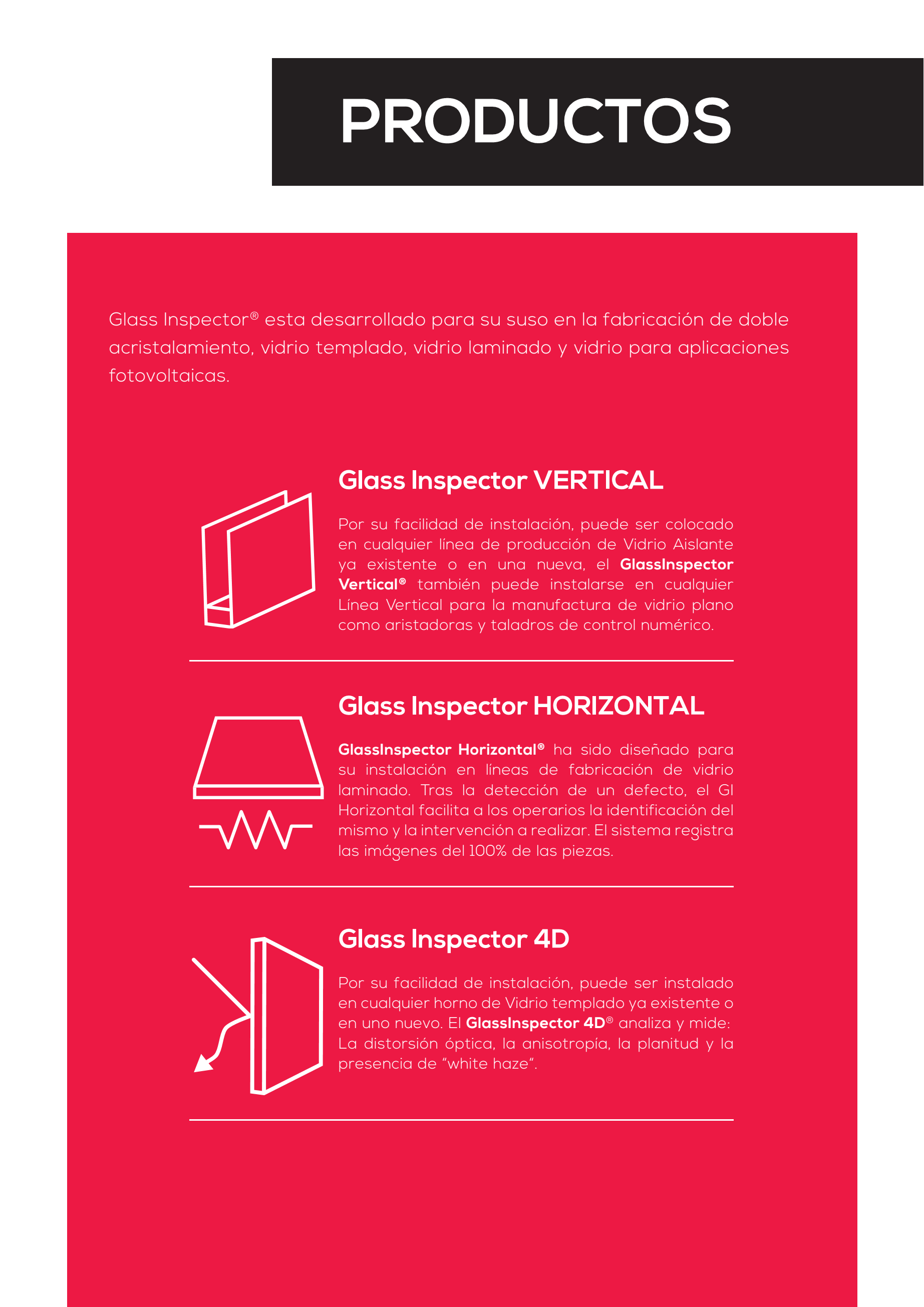

GlassInspector® VERTICAL

El GlassInspector® Vertical ha sido desarrollado y fabricado enteramente en España por técnicos españoles.

Por su facilidad de instalación, puede ser instalado en cualquier Línea de producción de Vidrio Aislante ya existente o en una nueva, el GlassInspector® también puede instalarse en cualquier Línea Vertical de Manufactura para el vidrio plano como aristadora ó taladros de control numérico.

El GlassInspector® necesita de muy poco espacio para su adaptación a cualquier tipo de línea de doble acristalamiento nueva ó ya instalada.

Para la instalación y el montaje del GlassInspector® no es necesario mover la línea de donde esta se encuentre ubicada,ni modifica su línea de modo alguno.

Características técnicas principales del equipo:

- El escáner es modular, por lo que es muy sencillo el mantenimiento.

- El GlassInspector® archiva todos los datos escaneados pieza a pieza, para en caso de una reclamación de un cliente poder verificar la pieza reclamada , pudiéndose seguir toda la trazabilidad de la misma, cómo fué fabricada y quien estaba al frente del equipo.

- Solo necesita un hueco de 30 mm entre los paneles de la línea , insistimos en que no es necesario el mover la misma.

GlassInspector® HORIZONTAL

El GlassInspector® Horizontal también ha sido desarrollado y fabricado enteramente en España por técnicos españoles.

Por su facilidad de instalación, puede ser montado en cualquier Horno de Templado ya existente, en cualquier Línea de Vidrio Línea de Laminado o por último en cualquier Línea horizontal de Manufactura.

El resultado es información técnica sobre cada pieza de vidrio fabricada, especialmente sobre la calidad superficial y de su masa de vidrio. Necesita muy poco espacio para su adaptación a cualquier tipo de línea de templado/laminado.

Características técnicas principales del equipo:

- El escáner es modular, por lo que es muy sencillo el mantenimiento.

- El GlassInspector® archiva todos los datos escaneados pieza a pieza, para en caso de una reclamación de un cliente poder verificar la pieza reclamada , pudiéndose seguir toda la trazabilidad de la misma, cómo fué fabricada y quien estaba al frente del equipo.

- Puede determinar la posición de la capa.

- Solo necesita un hueco de 30 mm entre los rodillos.

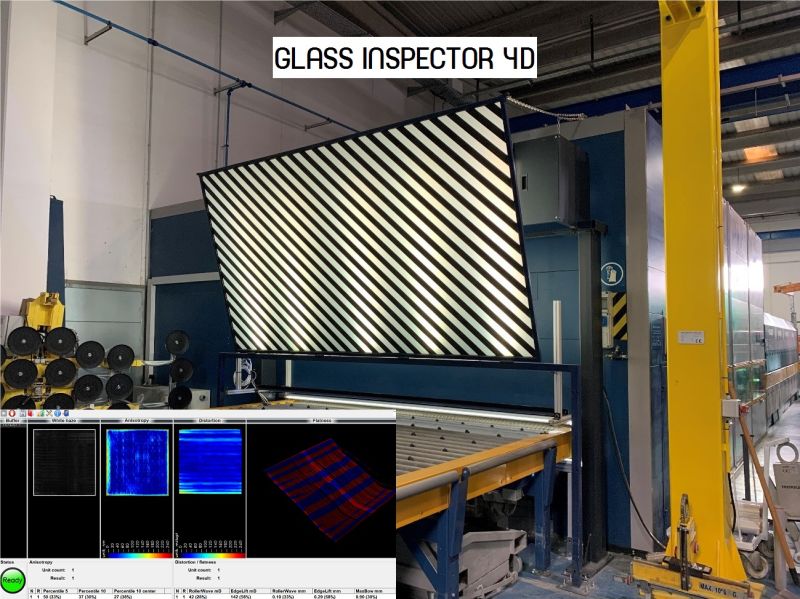

GlassInspector® 4D

El GlassInspector® 4D también ha sido desarrollado y fabricado enteramente en España por técnicos españoles.

Por su facilidad de instalación, puede ser montado en cualquier Horno de Templado ya existente.

El resultado es información técnica sobre cada pieza de vidrio fabricada en su horno de templado, especialmente sobre la calidad superficial y de su masa de vidrio. Necesita muy poco espacio para su adaptación a cualquier tipo de línea de templado.

Un scanner desarrollado por el equipo técnico de Glass Inspector, capaz de detectar los 4 principales defectos que puede tener un vidrio templado:

- Niebla blanca o white haze.

- Distorsión óptica.

- Planimetría.

- Anisotropía.Glass Inspector 4D , todas estas prestaciones en un solo equipo….no se puede pedir más .

Glass Inspector 4D , todas estas prestaciones en un solo equipo….no se puede pedir más

Los siguientes defectos, entre otros, pueden ser detectados sin problemas y a velocidad normal de trabajo

CATEGORÍAS DE LOS DEFECTOS | DESCRIPCIÓN DE LOS DEFECTOS | TIPO DE DEFECTO |

Contaminación de la Superficie del vidrio | Defectos en la Superficie del Vidrio que pueden quitarse con una limpieza adecuada | Suciedad, Huellas Digitales, Manchas (por ejemplo manchas producidas por cepillos y rodillos), Gotas de Aceite / Agua |

Superficie dañada del vidrio | Daño Físico en la Superficie del Vidrio, causado por su manipulación dentro de la fabrica (mesa de corte, canteadora...etc.) | Rayas, Puntos, Desportillados etc |

Defectos en el Interior del Vidrio | Defectos que se encuentran en el interior del vidrio y no han sido causados por su manipulación | Burbujas e Inclusiones en el propio vidrio |

Defectos de la capa del bajo emisivo o control solar | Daños o Defectos en la Capa Aplicada al Vidrio. Están definidas y son objeto de actualizaciones | Pin Holes (agujeritos en la capa), Rayas, Marcas, Deformaciones Visibles en el Recubrimiento,Falta de capa. |

Software a medida

Parametrizado y configurable, con posibilidad de añadir multiples perfiles para distintos niveles de calidad, campos y controles personalizados, etc.

Ofrecemos más que productos

En GlassInspector® ofrecemos más que productos; ofrecemos soluciones personalizadas para cada cliente desde el diseño de la maquina hasta el software, gracias a la combinación de nuestro know how con un buen uso de todos los recursos de los que disponemos.

GlassInspector® Cloud, aplicación web disponible para la consulta de los datos de inspección

Acceso a los informes de inspección mediante aplicación web, identificación de vidrio mediante entrada de datos directa (se introduce un codigo) o escaneo con camara (movil, webcam, etcétera) con distintos niveles de acceso pensado para el uso tanto de administradores como de clientes y proveedores.

Tu información a buen recaudo

Guarda tus datos de inspección mediante copias de seguridad, en almacenamiento local y/o remoto para así en caso de algun desastre poder recuperar toda la informacion recopilada hasta la fecha.

DESCARGAS

CATÁLOGO

¿Necesitas un sistema de inspección de defectos en vidrio?

Contacta con nosotrosNuestro trabajo

AMPLIA EXPERIENCIA EN EL MERCADO,

APRENDEMOS MÁS Y MEJORAMOS CON CADA INSTALACIÓN

Clientes

Cada vez son más los clientes satisfechos

Estamos aquí

Calle Arretxe Kalea, 15

20730 – AZPEITIA – GUIPÚZCOA, ESPAÑA