The 7 main reasons that cause problems of planimetry tempering glass:

1 deformation of ceramic rollers.

The deformation of the ceramic rollers will cause the glass to deform during the heating process, copying this irregularity.

2 ceramic roller wear.

Over time and due to intensive use of the kiln in production, the ceramic rollers lose diameter due to the glass abrasion process that takes place on them, causing them to lose diameter.

3 replacement of old ceramic rollers with new ones.

and not having taken into account that the difference in diameter generates a jump from the glass of the new rollers to the old ones, in addition to having different peripheral working speed, due to the difference in diameter with the same speed of rotation in the entire set of ceramic rollers (cause of White haze)

4 uneven rolls in the cooling process.

Many customers do not take into account the importance of the planimetry of the metal rollers + the planimetry of the Kevlar in the cooling zone, the glass in transition from the heating zone to the cooling zone has to find a good planimetry to avoid the glass is deformed.

5 temperature difference between the top and bottom of the glass.

The upper part of the glass was heated by radiation, while the lower part was heated by conduction of the energy transmission of the ceramic rollers, which causes the temperature difference between the glass surfaces and the problem of uneven heating of the glass .( The roller temperature control helps to solve this problem ) .

6 temperature difference between the center and the perimeter of the glass.

The glass begins to heat up around the perimeter where it has 3 surfaces to absorb energy (edge + upper face + lower face). Convection corrects this problem.

7 partial temperature difference of the glass.

This is usually caused by broken machine parts during the heating and cooling process, broken resistors, broken convention zones in the heating zone, as well as zones in the cooling zone not working properly.

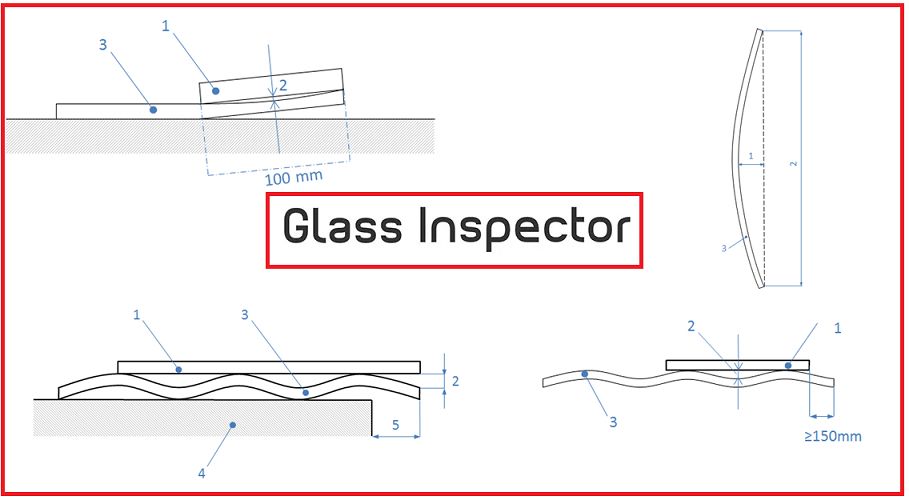

With Glass Inspector 4D you will be able to analyze and evaluate the panimetry of each glass produced :