The operators of the manufacturing line find themselves in addition to the typical problems of scratches, stains, finger marks, bubbles, inclusions in a float glass not coated … With the problems of the increasingly common use of Low-e glass.

The following definitions are given by the EN1096-1 standard and we will number them from 1 to 7 based on their appearance ;

1 Layer uniformity defect: slight visible variation in color, reflection or transmission.

2 Stain: coating defect larger than spot defect, often irregular in shape, partly speckled in structure.

3 Point defect: visual point disturbance of transparency looking through the glass and of visual reflectance looking at the glass. Spot, pinhole, and scratch are types of point defects.

4 Spot: A defect that commonly appears dark against the surrounding coating, when viewed in transmission.

5 Pinhole: punctual void in the coating with partial or total absence of coating and normally contrasts clear in relation to the coating, when viewed in transmission.

6 Scratches: A variety of linear puncture marks, the visibility of which depends on their length, depth, width, and position.

7 Cluster: accumulation of very small defects that give the impression of a stain.

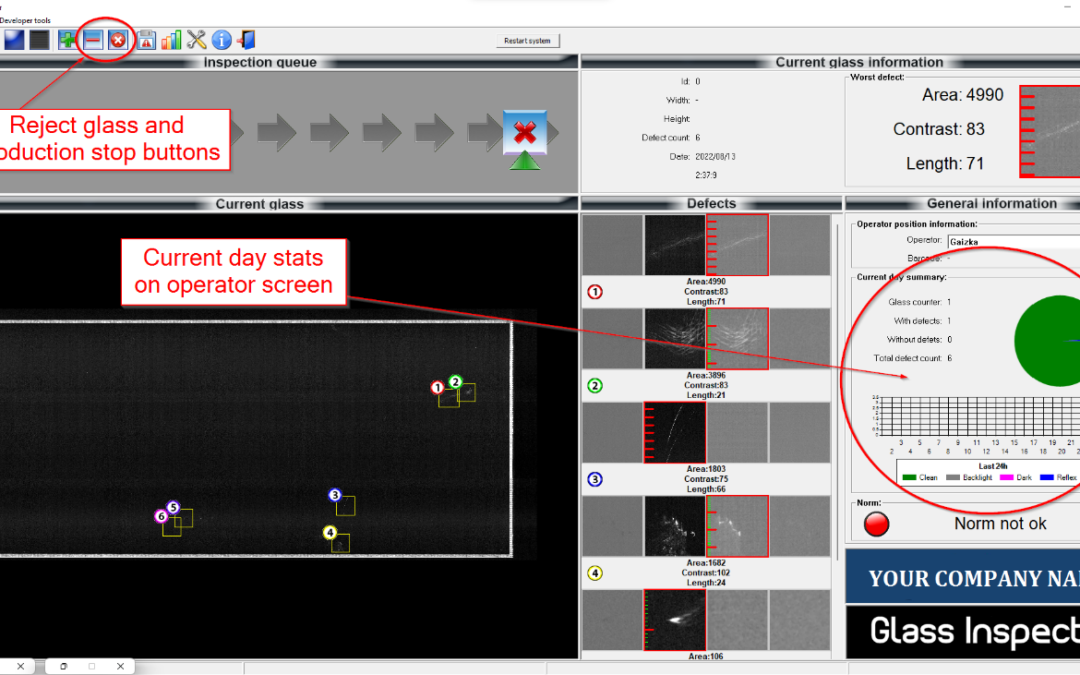

Glass Inspector only for the location and evaluation of all these defects that can occur in a low emissive glass dedicated 2 types of lighting, our technicians were satisfied with the location of these defects with our “Reflex” system but they have gone one step further and added a new additional system to verify that the defect seen by the “Reflex” is in the glass .Always innovating always improving.