1. Surface Inspection: Artificial vision systems use high-resolution cameras to capture images of the surface of tempered glass.

2. Defect Detection Algorithms: Advanced algorithms are employed to detect defects in the glass variations.

3. Dimensional Analysis: Artificial vision systems can also measure the dimensions of tempered glass products to ensure they meet specifications.

4. Edge Inspection: The edges of tempered glass products are critical for their structural integrity..

5. Automated Sorting: Based on the inspection results, the tempered glass products can be automatically sorted into different categories, such as “pass” or “fail.” Defective products can be removed from the production line for further inspection or repair.

6. Data Analysis and Reporting: The results of the quality control inspection are recorded and analyzed to identify trends and patterns in the quality of the tempered glass products. This data can be used to improve manufacturing processes and reduce defects over time.

Overall, quality control with Glass Inspector in tempered glass helps manufacturers ensure that their products meet high standards of quality and safety. By automating the inspection process, it also increases efficiency and reduces the likelihood of human error.

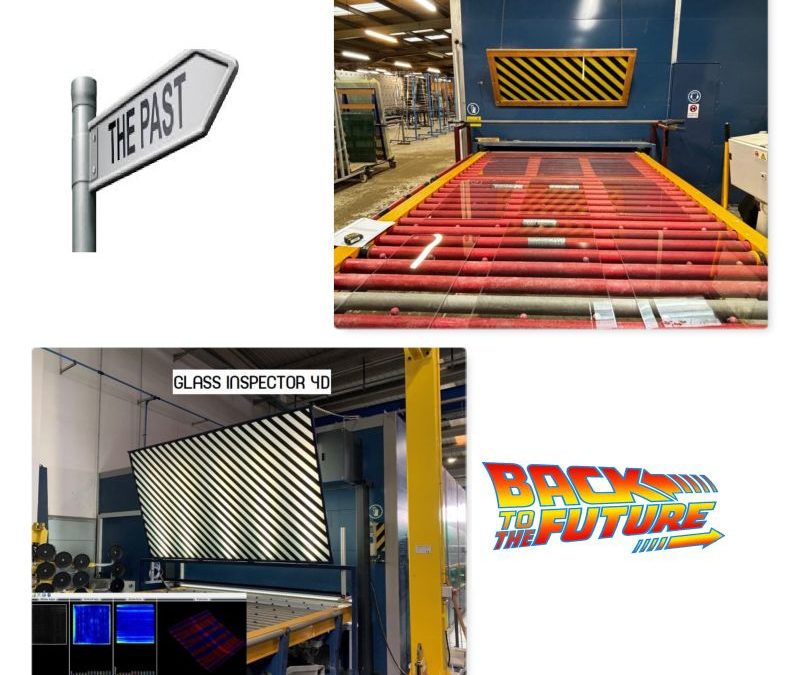

Glass Inspector 4D was born and developed to analyze, evaluate and qualify all the tempered glass produced by your tempering furnace .

– Planimetry

– Optical distortion

– White haze

– Anisotropy

……..all in one machine

For more information visit our web site www.glassinspector.com

Or write to : sales@glassinspector.com

GLASS INSPECTOR “ BORN TO INSPECT YOUR GLASS “