Glass Inspector 4D versus

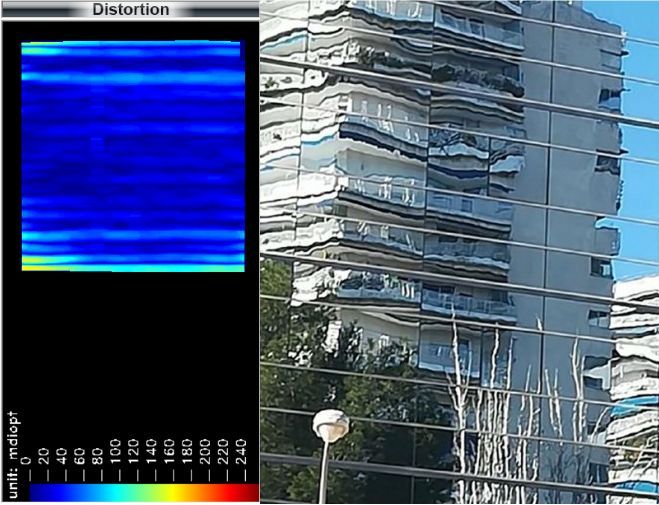

Optical Distortion in a Tempered glass

The visual distortions in glass are caused by the delay in light reflection between these two surfaces of glass causing two light waves to combine, It is a defect produced during the glass tempering process, a superficial distortion is produced by reducing the flatness of the surface, known as roller wave. This wave is generally seen in reflection.

– Overall bow

– Roller wave distortion

– Edge lift

– Perimeter deformation

Until the invention of optical measurement equipment, the manufacturer of tempered glass classified tempered glass into two categories;

– With low optical distortion “ aceptable “

– With high optical distortion “ unacceptable “

And to reach these qualifications use a visual method :

· You should stand no closer than 3m away from the glass face.

· You should face the glass head-on at a 90-degree angle.

· Glass inspections should be done in natural daylight but not directly towards the sun and with no visible moisture on the glass.

· You should look through the glass rather than at the glass.

· You should exclude a 50mm wide band around the edge of the glass from your inspection.

….ALL THIS IS ALREADY HISTORY.

Glass Inspector 4D is able to measure the optical distortion on glass tempered by comparison with patterns of the reflected image, the optical distortion produced by lack of flatness in the glass is measured. The result is given in diopters (a diopter is the distortion created by a radius of curvature of one meter). The resolution of the system is 0.002 diopters.

THIS IS THE PRESENT AND FUTURE – GLASS INSPECTOR 4D.